Vertical CNC Machine Center Vmc1160 CNC Milling Machine

N º de Modelo.

VMC1160

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(milímetro)

Performance Classification

Economical CNC Machine Tools

Certificación

ESTA, RoHS, ISO 9001

Condition

Nuevo

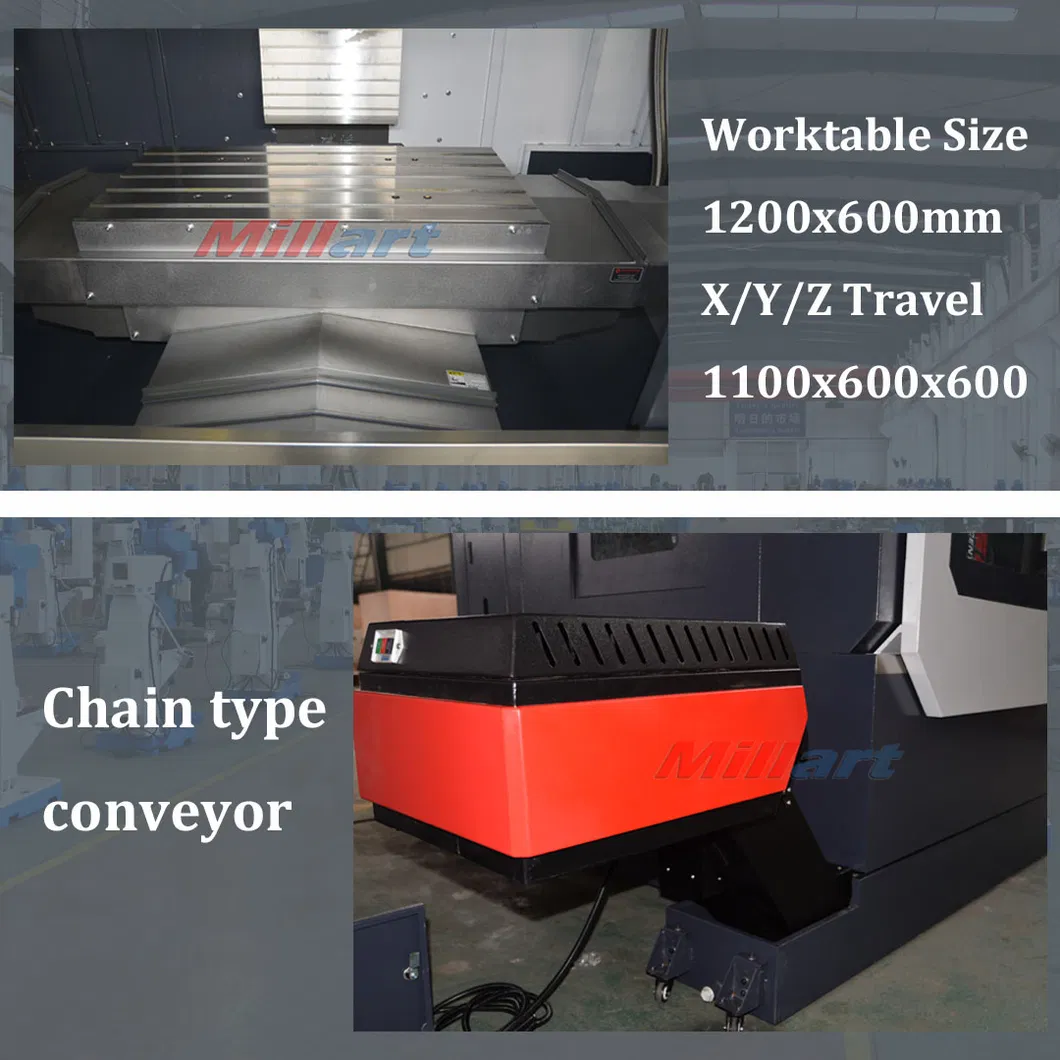

Worktable Size

1200X600 mm

X/Y/Z Travel

1100/600/600 milímetro

Spindle Taper

Bt40

Main Motor Power

7.5/11 Kw

Marca comercial

L&T

Paquete de transporte

Wood Case

Especificación

CE ISO9001 RoHS

Origen

Tengzhou China

Código hs

8457101000

Descripción

Vertical CNC Machine Center VMC1160 CNC Milling Machine

Main configuration & accessories:

Main configuration & accessories:1. Resin sand casting, Meehanite HT-300;

3. X, Y, Z rails adopt stainless steel telescopic cover;

4. Roller type linear guideway from Taiwan

5. Ball lead screw from Taiwan

6. Standard with belt driven spindle, optional for direct driven spindle;

7. Taiwan pneumatic cylinder;

8. Taiwan ATC, umbrella type and disc type are available;

9. Import bearings for leadsrews;

10. Import coupling;

11. Headstock Nitrogen balance system as option;

12. Full enclosed cover;

13. Rigid tapping;

14. Spindle center ring blast;

15. Work lamp;

16. Pilot lamp;

17. USB and Internet interface;

18. Manual pulse generator (millas por galón);

19. Centralized automatic lubrication system.

20. Cooling system.

21. Heat exchanger for electrical cabinet ;

22. Leveling blocks & bolts;

23. Toolbox and tools;

24. CNC controller: KND,GSK, HNC (China); SIEMENS, FANUC, MITSUBISHI, FAGOR, etc..

Technical parameter:

3. X, Y, Z rails adopt stainless steel telescopic cover;

4. Roller type linear guideway from Taiwan

5. Ball lead screw from Taiwan

6. Standard with belt driven spindle, optional for direct driven spindle;

7. Taiwan pneumatic cylinder;

8. Taiwan ATC, umbrella type and disc type are available;

9. Import bearings for leadsrews;

10. Import coupling;

11. Headstock Nitrogen balance system as option;

12. Full enclosed cover;

13. Rigid tapping;

14. Spindle center ring blast;

15. Work lamp;

16. Pilot lamp;

17. USB and Internet interface;

18. Manual pulse generator (millas por galón);

19. Centralized automatic lubrication system.

20. Cooling system.

21. Heat exchanger for electrical cabinet ;

22. Leveling blocks & bolts;

23. Toolbox and tools;

24. CNC controller: KND,GSK, HNC (China); SIEMENS, FANUC, MITSUBISHI, FAGOR, etc..

Technical parameter:

| Artículo | Unidad | VMC1160 |

| Capacity | ||

| X axis travel | milímetro | 1100 |

| Y axis travel | milímetro | 600 |

| Z axis travel | milímetro | 600 |

| Spindle nose to worktable | milímetro | 120-720 |

| Spindle center to column | milímetro | 650 |

| Leadscrew size | ||

| Leadscrew diameter | milímetro | Φ40 |

| Linear guideway width | milímetro | 45/45/45 |

| Worktable size | ||

| Worktable Length | milímetro | 1200 |

| Worktable width | milímetro | 600 |

| Max loading capacity | kg | 800 |

| Spindle | ||

| Spindle speed | rpm | 8000 |

| Main motor power | KW | 7.5/11 |

| Spindle taper | BT40 | |

| Feeding system | ||

| Fast moving speed (X/Y/Z) | m/min | 36/36/36 |

| Cutting speed | mm/min | 1-10000 |

| Feed motor power | KW | 3/3/4.5 |

| Tool Magazine | ||

| Capacity | piezas | Arm 24 |

| Max tool diameter | milímetro | 120 |

| Max tool weight | kg | 8 |

| Max tool length | milímetro | 300 |

| Exactitud | ||

| Positioning accuracy | milímetro | 0.008 |

| Repeat accuracy | milímetro | 0.005 |

| Machine dimensions | ||

| Largo | milímetro | 3300 |

| Ancho | milímetro | 2400 |

| Height | milímetro | 2800 |

| Peso | kg | 6900 |

Standard accessories:

| Fanuc 0i TF control system | Automatic lubrication |

| Taiwan Spindle: 8000rpm | Coolant system, |

| X/Y/Z axes: Fanuc servo drive motor | Work lamp, |

| Main motor: Fanuc spindle motor | Tri-color indication lamp |

| 24 tools Umbrella type | Air gun |

| USB for information transfer | Heat exchanger in cabinet |

| Rough cutting of thread | 3-Axis linear guideway from Taiwan Hiwin |

| Full closed cover | Ball leadscrew from taiwan Hiwin |

Optional accessories:

| Automatic chip conveyor & chip bucket (Chain type) | Automatic chip conveyor & chip bucket (Screw type) |

| Spindle direct driven, speed 12000 rpm | Spindle oil cooling |

| Spindle center water spray | Nitrogen balance cylinder |

| Air conditioner for electricity cabinet | 4th Axis or 5th Axis |

Company information: Contáctenos:

Contáctenos: