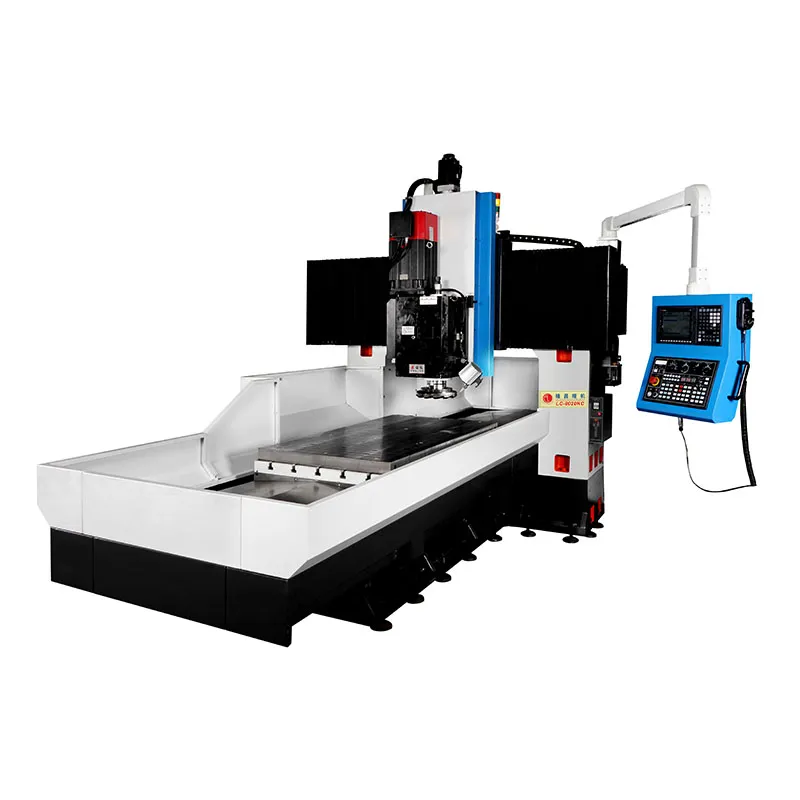

CNC Lathe Machine Tool for Mold Base Milling and Cutting

Descrição

Descrição do produto

Selling Point

1.Firmly hold the workpiece, ensure the safety of the processing process, through the demagnetization controller and machine tool connection, through the button operation demagnetization, very convenient to use, improve the machining efficiency of the machine up to more than 80%

2.The large spiral normal blade provides a small cutting tool for stable cutting, and the thickened reinforcing blade has a finishing treatment

3.The friction resistance is very small, and it has the characteristics of high precision, reversibility and high efficiency.

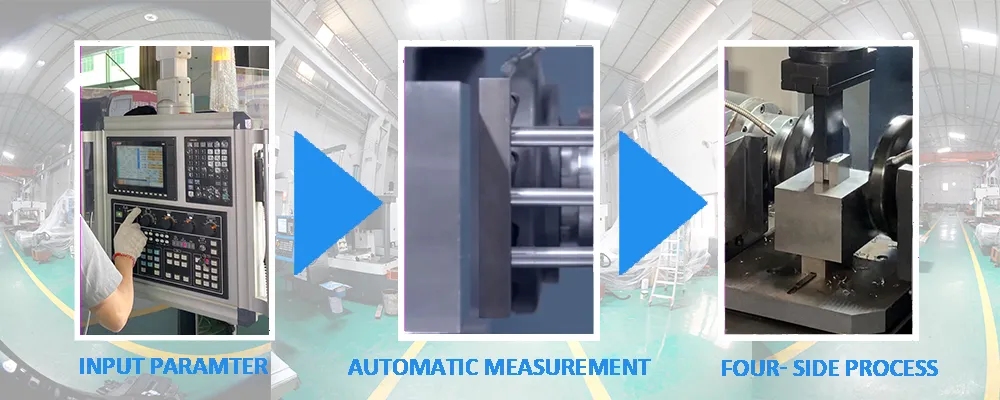

4.Workpiece processing coarse, fine milling integration, numerical control system control size setting processing size, automatic measurement, automatic coarse, finishing, reduce the working intensity of the operation staff, improve the processing efficiency, ensure the flatness of the workpiece, roughness.

Automatic Centering

Alta Precisão

Base Data

| Main Specification | ||||

| Items | Nome | LC-8020NC / BH-1220MAL | ||

| Cutting capacity | Control axis number | 3 | ||

| Cutting capacity mm | 5 | |||

| Length*width*Height mm | 2000*1200*500milímetros | |||

| Worktable | Dimensions mm | 2000×1000 | ||

| Max loading weight kg | 6000 | |||

| Spindle | Spindle speed(Infinitely variable speeds) rpm | 75-505 | ||

| Spindle power kw | 9.5 | |||

| Spindle taper | BT50(7:24) | |||

| Spindle speed sections (Manual) | / | |||

| Cutter diameter mm | 250 | |||

| XYZ axis | X/Y/Z axis motor power kw | Same 3KW/15N.M | ||

| X/Y/Z Max feed speed m/min | 8/5/3 | |||

| X/Y/Z work range mm | / | |||

| X/Y/Z Max cutting speed | 5M/Min | |||

| Accuracy | Accuracy for dimension mm/300mm | 0.03 | ||

| Tank capacity | Hydraulic oil tank L | / | ||

| Lubrication oil tank L | 20 | |||

| Power | Power | AC440V±10%, 24KVA | ||

| Net weight | Machine net weight KG | 10000 | ||

| Product size | Product size | L5600*W2500*H2700mm | ||

| Main parts | ||||

| Sort | Nome | Quantity | Tamanho | Origem |

| Machinery | Parafuso de esfera (XYZ axis) | 3 | XZ-R5010 S- R4010 | Taiwan TBI |

| Guide rail | 3 | / | Domestic | |

| Main Spindle (Vertical) | 1 | Gearbox 1:6 | Taiwan ENLOG | |

| Flexible stainless steel plate shield of worktable | 2 | SPCC | Domestic | |

| Base casting | 1 | / | HT300 | |

| Automatic lubricating machine | 1 | 1/4HP Pump | Domestic | |

| Oil line | N | 4/6 | Domestic | |

| Consequência | / | / | Japan NSK | |

| Electrical appliances | CNC system | 1 | E80/EJ | Japan Mitsubishi |

| MPG | 1 | HC121 | Japan Mitsubishi | |

| Servo motor | 3 | / | Japan Mitsubishi | |

| High precision electromagnetic table | 1 | 1500*800milímetros | Taiwan Brand | |

| Spindle motor | 1 | 15KW-1500rpm | MK | |

| AC contactor | / | / | Schneider | |

| Relay | / | / | Schneider | |

Detailed Images

Manufacturing

APPLICATION

Perfil da companhia

The company has absorbed the advantages of NC technology from Germany and Japan and gathering the leading technology from domestic and foreign industries. All machines are marked ISO 9001 and CE, exported to 58 countries. Main products: Duplex milling machine, Vertical gantry milling machine, Side milling machine, Powerful gantry grinder, Cutting machine, Chamfering machine etc.

We are committed to be the No.1 brand in 6 side milling machine and one-stop service supplier in mould processing industry, serving global client , promoting mould processing industry to reach new level.

Workshop Show

Factory Address: No.1 Yintai North Road, Shutian, Humen Town, Dongguan, City, China

R&D Capacity: Own Brand, ODM, OEM

No. of R&D Staff: 160

No. of Production Lines: Above 10

Annual Output Value: US$15Million

After-Sale Service

1. Installation services for free.

2. Operation training for free.

3. We will create files for every client, to track product quality and after service.

4. Providing one year (12 months) warranty for free except for the wrong operation by the user . The spare part is not on the free warranty list.

5. Providing maintenance and repair service termly.

6. Seller will provide solution way within 72 hrs once receiving A-F service request from the buyer.

Perguntas frequentes

Q: Are you a manufacturer or Trading Company?

UMA: We are a innovative interprise with rich import & export experience and 10 professional production line.Warmly welcome you to visit our factory.

Q: Do you have Agency in my country?

UMA: With the development of our company, we are expanding export gradually to get a bigger worldwide share of marketing.(The United States/ Korea / India / Southeast Asia etc.). Till now, we have agence in India/Korea/Thailand/ Vietnam, please feel free to contact us to get more detail.

Q: How can I Install the machine, and What should I do if my machine was broken down

UMA: We provide free installation service to your home. If your machine was broken, please contact us immediately and we will give you solution way within 48 hours.

Q: Can you support OEM Service?

UMA: Sure, As your requirement, We would like to make the plan and provide the best service for you.

Q: How can I choose the most suitable machines ?

UMA: Please let us know your specifications,we can choose the best model for you , or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .